Earlier this month I attended the 2024 FSPCA Annual Conference. Prior to the conference I was able to complete a Lead Instructor’s refresher training on Preventive Controls for Human Food Curriculum. The most recent version of the curriculum called “PCQI training” comes from 2016. It was about time for the FSPCA and FDA to update the materials and account for changes and new approaches in how food companies build their food safety systems.

Although the Preventive Controls regulation has not changed, over the years, FDA developed new techniques on how they conduct regulatory compliance inspections in food facilities. Based on their findings and data they collect through Reportable Food Industry, outbreak investigations and studies there are additional factors to be considered when evaluating food safety systems of food safety plans.

The new version of Preventive Controls for Human Food Curriculum reflects those factors and the new approach in hazard identification. The regulation has always required that companies recognize hazards in ingredients that are controlled by the suppliers. Supply Chain Program under 21 CFR 117 (G) clearly requires food processing, manufacturing or repacking facility to recognize supplier managed food safety hazards and analyze if preventive controls are needed to avoid serious health consequences to consumers.

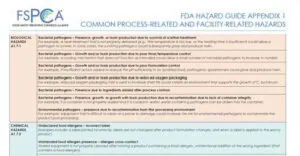

In hazard identification the companies do not always consider all factors related to their supplier’s operation. FDA developed a list of potential processes and facility related food safety hazards that is to be used when identifying hazards in raw materials and ingredients. This is a valuable aid that was included as part of Appendix 1 (Hazard Analysis and Risk-Based Preventive Controls for Human Food: Draft Guidance for Industry). The list includes a set of questions about product formulation, lethal treatment, temperature controls, packaging, allergens, environmental pathogens and other facility / process related aspects.

With the new technique, it appears that companies will need to do a whole lot more investigating on what their suppliers actually do and what is their food safety system.

During the conference some participants expressed concerns that smaller businesses may not have the resources available for all this work, especially if they produce multicomponent food.

Going through the list of questions in the Appendix is to ensure that ingredients we get are safe and won’t affect our operation. Looking at the outbreaks, it seems that Supply Chain Controls are often either omitted or improperly designed. This is partially due to the receiving facility not having a good understanding of the supplier’s food safety practices and site-related conditions.

From a larger point of view, the resources to conduct proper hazard analysis may be substantial and the process time consuming, but at the end of the day it is still cheaper than a product recall. Very often businesses blame their supplier for wrongdoing, yet the same businesses are not willing to spend time looking at their supplier’s food safety plans. Here the FDA gives us a tool to avoid supplier related food safety issues and protect your brand.

With this approach it looks like supplier audits will be on the rise. For those without qualified auditors, the emphasis should be on the full audit reports from third party reputable certification bodies. A well-written audit report can provide valuable information about the company’s food safety system and compliance with relevant food safety legislation including CGMPs and Preventive Controls.

In lieu of a 3rd party audit a well-designed supplier questionnaire may also provide great information.

Again, none of this is a new requirement but rather additional tools and working aids to achieve compliance. As always, if you feel you can’t do it on your own, give us a call or fill out our CONTACT FORM. BD Food Safety Consultants LLC will be glad to assist!